What is a good way to solder wires that will last for years? I bought a boat from a guy whose day job was building electronics that orbit the earth. This is how he soldered wire.

As an Amazon Associate, at no additional cost to you I earn from qualifying purchases. If you don’t see Amazon product images on this page, or the ads seem incomplete, click here.

Step-by-step

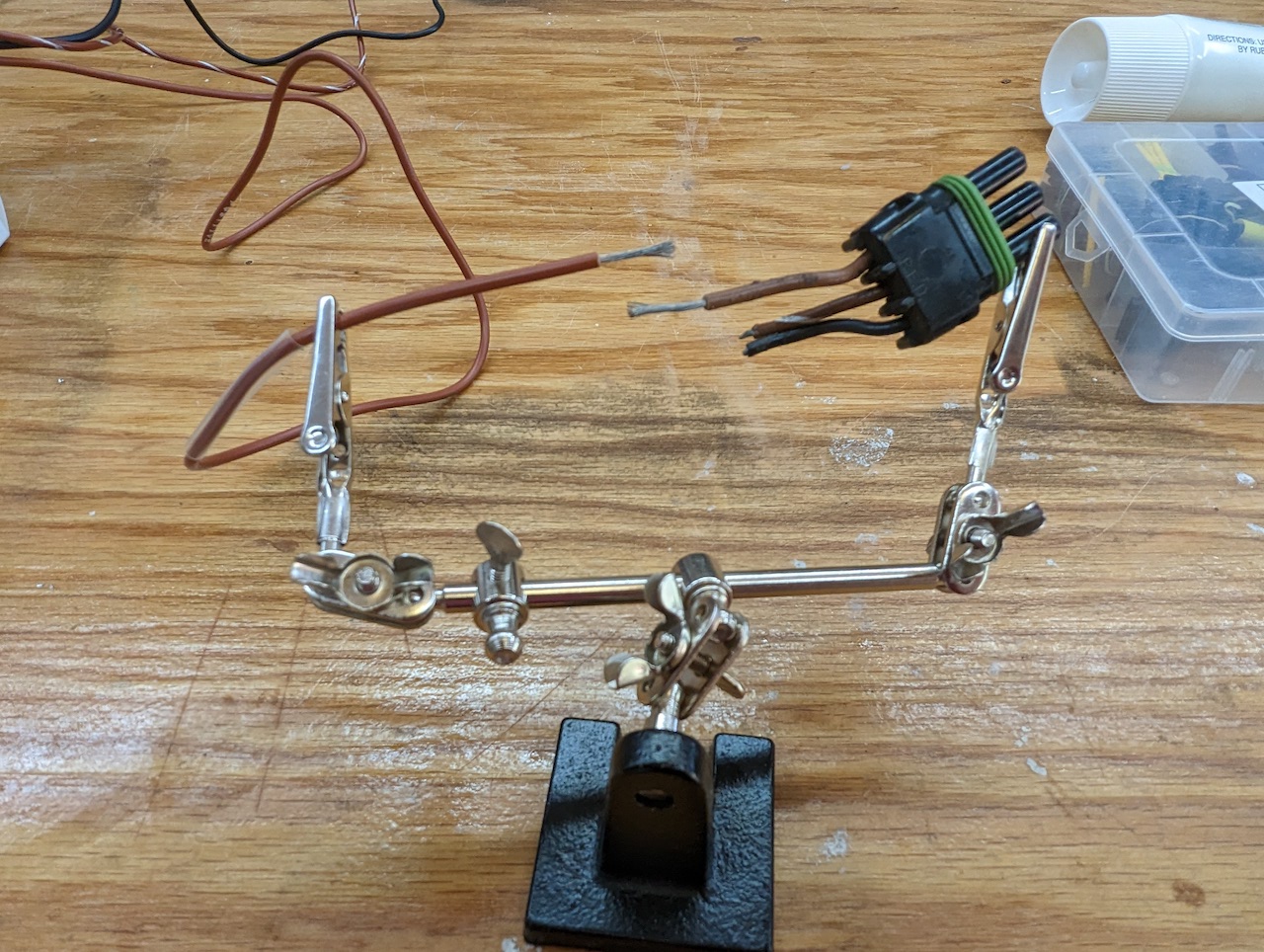

In this example, I’ll walk through how I would solder wires for use in a wet environment. To get started I have stripped about half an inch of wire from each of the brown wires. The Klien wire strippers are the best and mechanically one of the most interesting tools that I own.

The Helping Hands are used to hold wires in place. I’ve used larger versions of this type of helper device, but I have found I only need two extra hands. You can spend a lot more but this is all you will need.  Helping Hands are a big help for more complicated tasks

Helping Hands are a big help for more complicated tasks

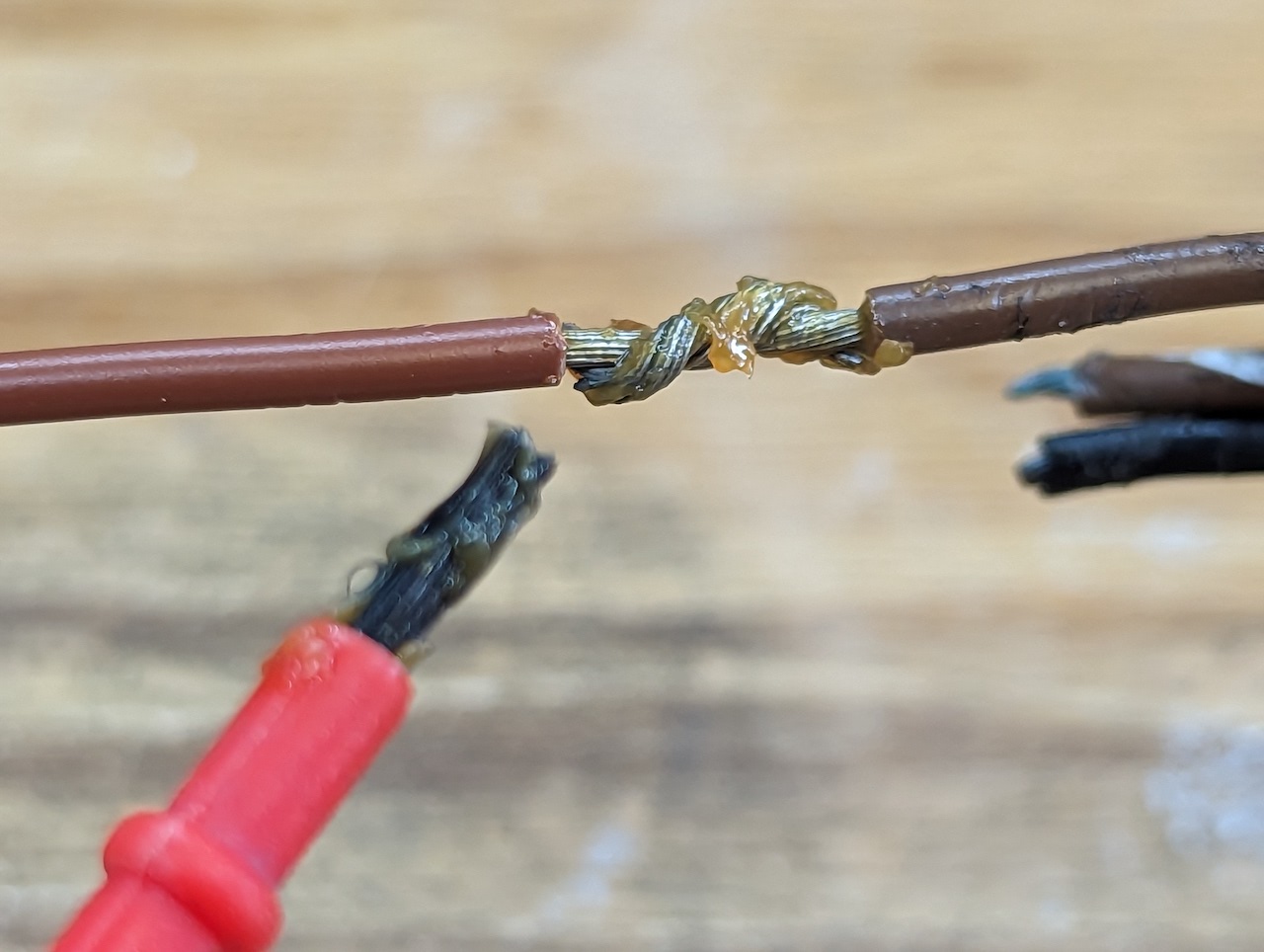

Next you twist the wires together, without making any lumps, get has much contact between the two wires as possible. Make sure no wire ends are sticking out, they can puncture the shrink wrap installed later Now apply Rosin Soldering Flux to make the next step easier.

I solder the wire using lead solder and a butane soldering iron. You can see in the picture that the wire casing is a bit charred but that was not by me, this wire was used in a rather harsh environment. I think it was riding on an exhaust pipe for a while. I’ll cover most of the char with shrink wrap.

Next I protect the exposed wire with No-OX-ID special grease This improves conductivity and protects the wire from exposure to water and humidity.

Finally I slide the heat shrink over the soldered wire and apply heat with a heat gun. Note how well the clear shrink tube shows the grease protecting the solder joint. Unless you are showing polarity with red or black shrink tube, or need some other color scheme, use clear tubing.

Summary

It is nice getting things done, with the right tools, knowing that you probably won’t have to mess with it again for a long time. The connection between these two wires that should last for years.

Here is a good video on the whole process.

Tools Used

Klien Wire Strippers

These wire strippers from Klein are a bit expensive, but every splice is perfect. You don’t want to nip any strands of wire, each strand counts.

Helping Hands

The Helping Hands are used to hold wires in place. I’ve used larger versions of this type of helper device, but I have found I only need two extra hands. You can spend a lot more but this is all you will need.

Rosin Soldering Flux

I’ll admit, I have not used this but it has great ratings. Buy this one time and it will last forever. You only use a little bit at a time.

Lead Solder

I only use solder with lead in it. The lead-free solder might be OK for some applications, but solder connections don’t look as good to me.

Butane Soldering Iron

These soldering irons are great. My first one probably lasted 15 years. They get nice and hot very fast and you don’t need to drag an extension cord around you. You can also use it as a small torch.

No-OX-ID Special Grease Compound

This grese will protect your wire from corrosion. Good stuff, buy it, use it.

Heat Shrink

This is a nice collection and inexpensive tool. The stuff shrinks nicely.

Mini Heat Gun

This unit is small enough to fit in my toolbag and gets the job done.